TMS GROUP is a team of professionals that specializes on engineering design, production of aspiration systems, supply of compressor equipment and industrial fans as well as manufacture and installation of metalware any level of sophistication.

Our own production facilities, modern equipment, experience and workers professionalism create the basis that allows our enterprise to be a leader and advantageously differ from competitors.

Strict multilevel control on every stage of manufacture is a guarantee of production compliance to the highest European and global standards.

We guarantee the dust concentration on an output of installation no more than 10 mg/m3 that meets all the worldwide norms.

During the production of any equipment used in numerous sectors of the industrial sector (in packaging, agriculture, textile, chemical, food, automotive and other industries), compressed air is used along with other energy carriers.

The only source of compressed air to date are compressors. Along with the evolving technologies and the continued growth of the industry, significant progress was noted in the production of this equipment.

High performance, efficient operation under all conditions and ensuring a reduction in operating costs are the basic rules of competition in the market of compressor equipment.

Fans are devices that depending on the version and category are used in various industrial plants to move a stream of clean or polluted air, a mixture of gases, steam and smoke.

Fans can be divided into three main groups: axial, centrifugal and special. As a rule, axial fans are used for higher airflow speed at lower resistances, and centrifugal ones for lower flow rates at higher resistances.

Air duct is a system of metal tubes that is used in any ventilation system.

The intent of air ducts is circulation and distribution of air around the place, moving and redirection the gas or dust air mixtures, as well as transportation of different materials.

Supply and output of air through system of air ducts can be implemented naturally and forcibly with fans help.

Cyclones are used in production for removing large dust elements from air flow or as product separator in air-feeding.

Those cyclones have an accelerative principle of cleaning with the use of centrifugal force. Cyclone dust collectors are used in every sphere of industry.

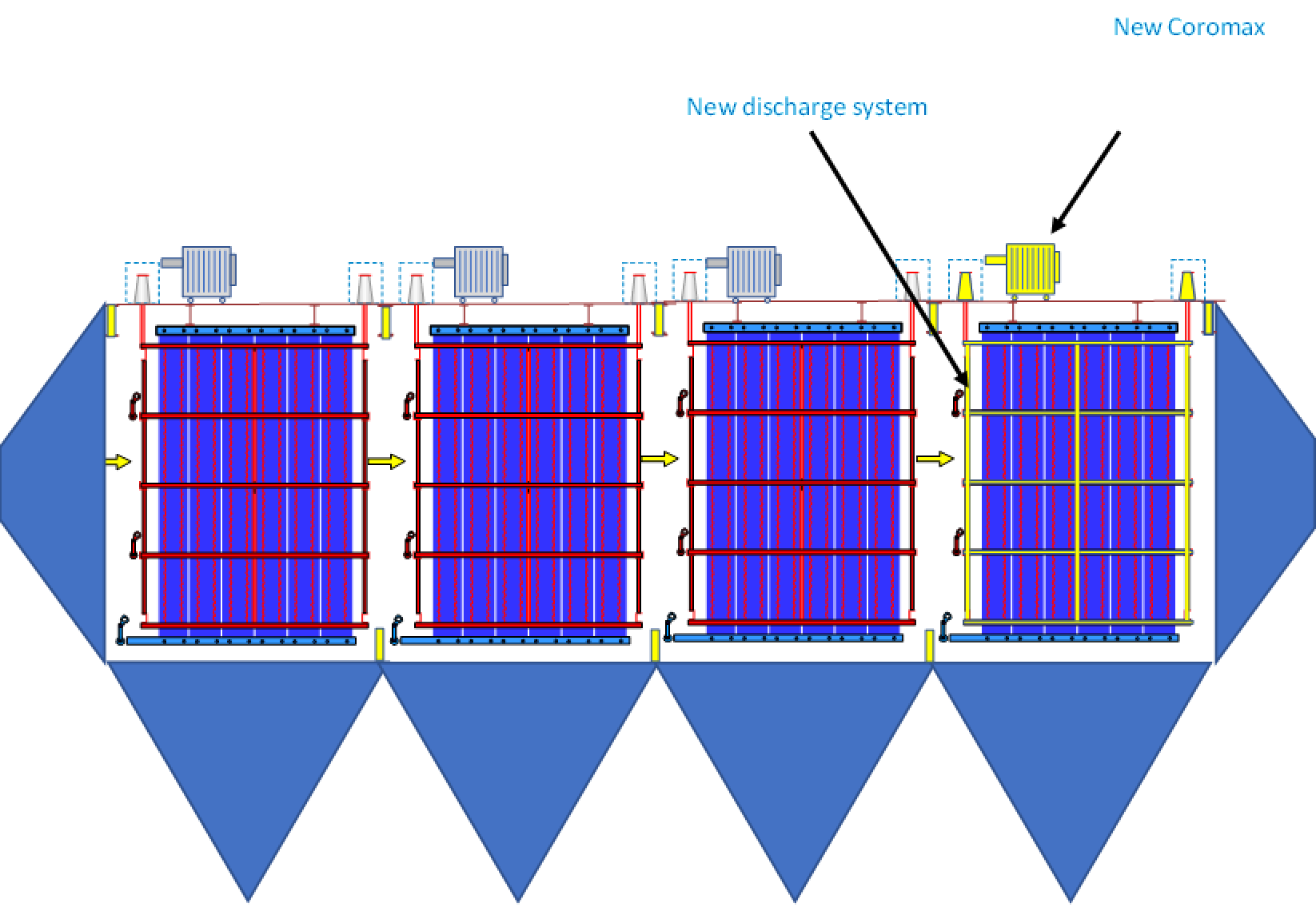

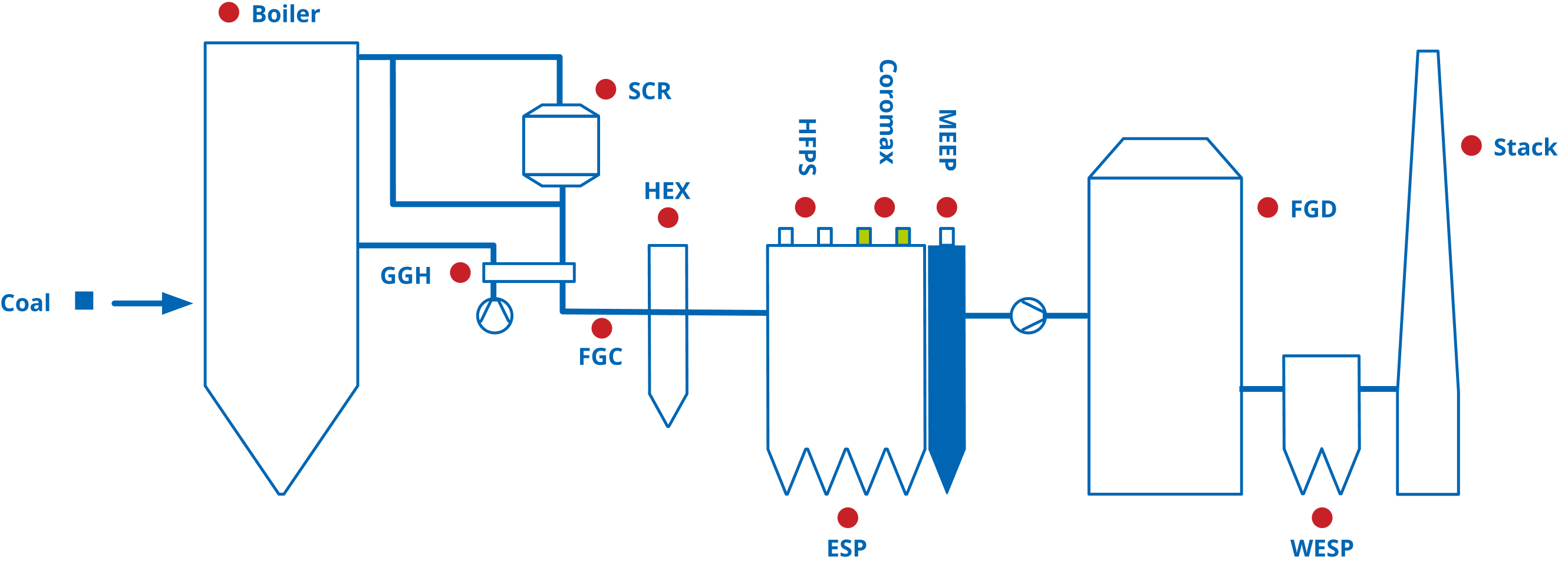

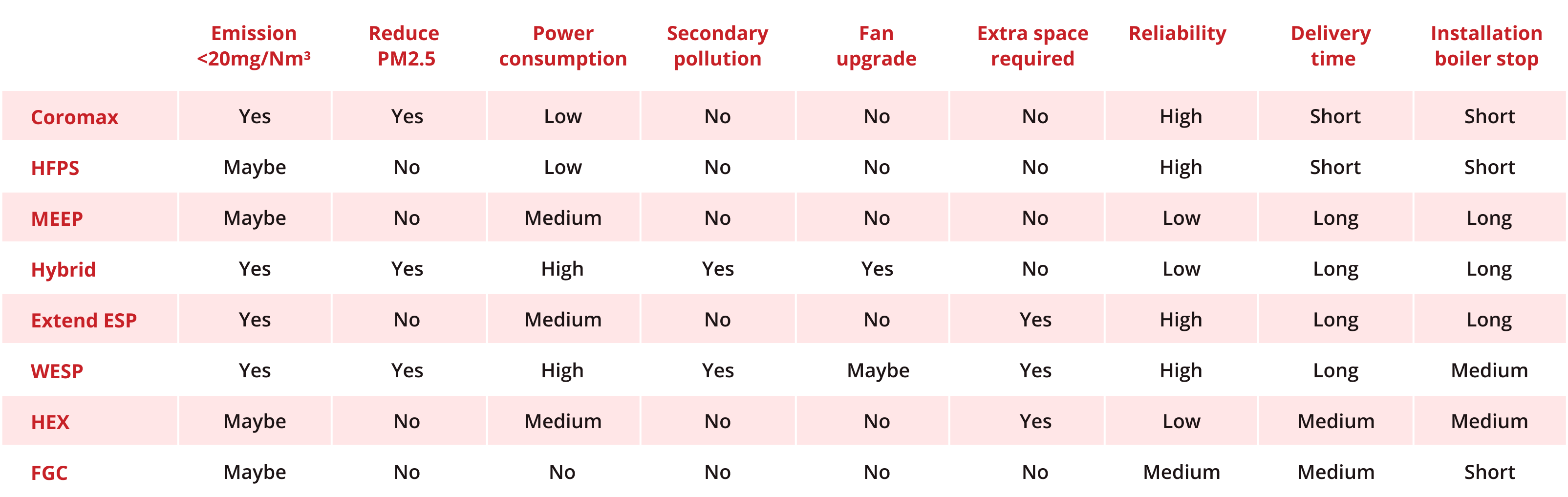

The Coromax micro-pulse power supply is a family of high-voltage power supplies for electrostatic precipitators aiming at reducing dust emissions and electric power consumption. They are also extremely efficient to collect the hazardous fine particles, like the PM1 and PM2.5 and can effectively reduce mercury content.

The Coromax micro-pulse power supplies generate a special voltage waveform in the electrostatic precipitator, which is characterised by a smooth base voltage superimposed by extremely narrow pulses. They are designed to capture high-resistivity dust, such as dust emitted by coal-fired power plants and steel sintering plants.

On top of a base DC voltage that can reach up to 60 kV, micro-pulses are superimposed, with a nominal pulse width of 75 µs and an amplitude of up to 80 kV. This allows for a total maximum peak voltage of up to 140 kV. The rated pulse repetition frequency is equal to 100 pulses per second (PPS).

The Coromax mk4 is controlled by the EPCU, a specially designed microprocessor-based control unit. Using a proprietary and patented control strategy, the EPCU can optimally control the amplitude of the base voltage, the amplitude of the pulses and the pulse repetition frequency. An EPCU can also be used to control rapping and heating systems.

No need to change the internal parts.

Baosteel Group Corporation, Shanghai selected FLSmidth for ESP upgrade and Coromax pulse systems.

Baosteel and the local authorities in Shanghai reached an agreement on reducing the high level of dust emission from the plants coal-fired boilers of 350 MW. The project scope involved upgrading of ESPs with two additional fields and Coromax pulse systems.

A total of 16 Coromax units for all new sections deliver a dust emission which is significantly reduced and meets the local requirement of maximum 20 mg/nm3.

Shenzhen Energy Group, one of the main power generation companies based in Shenzhen, Guangdong, has on their Mawan power plant four power boilers of 300 mw and two boilers of 320 mw.

To succeed with the required emission reduction, a comprehensive upgrade of the existing ESPs which are more than 20 years old, was essential. The project also involved replacing of the existing DC power supplies with Coromax on the three fields – a total of 12 set per boiler.